Today, zirconia has virtually become a material that is “present in almost every patient’s mouth.” From single crowns and long-span bridges to full-arch restorations, zirconia has proven its stability, high strength, and wide clinical applicability. However, not all zirconia materials are the same. Even subtle differences in composition, structure, and manufacturing technology are what allow certain materials to stand out and deliver real value in modern restorative practice.

Zirconia and the timeless challenge: esthetics combined with strength

Since its introduction into dentistry, zirconium oxide has been recognized for its outstanding mechanical stability. However, in areas with high esthetic demands—particularly the anterior region—zirconia restorations are often veneered or layered (stratified) with ceramic to individualize shape, color, and optical effects.

The challenge lies in the fact that this veneering ceramic, while offering refined esthetics, has relatively low flexural strength, typically ranging from 80 to 130 MPa. When the stratified layer is too thick, the risk of chipping increases, especially in high-stress areas such as incisal edges and cusps. Under repetitive masticatory loading, these mechanical limitations can quickly become apparent.

In contrast, highly translucent zirconia—the new generation of zirconia materials—not only provides impressive esthetic results but also exhibits significantly higher strength compared with traditional veneering ceramics. This has laid the foundation for a new approach to restorative design.

The ideal solution: function-oriented material zoning

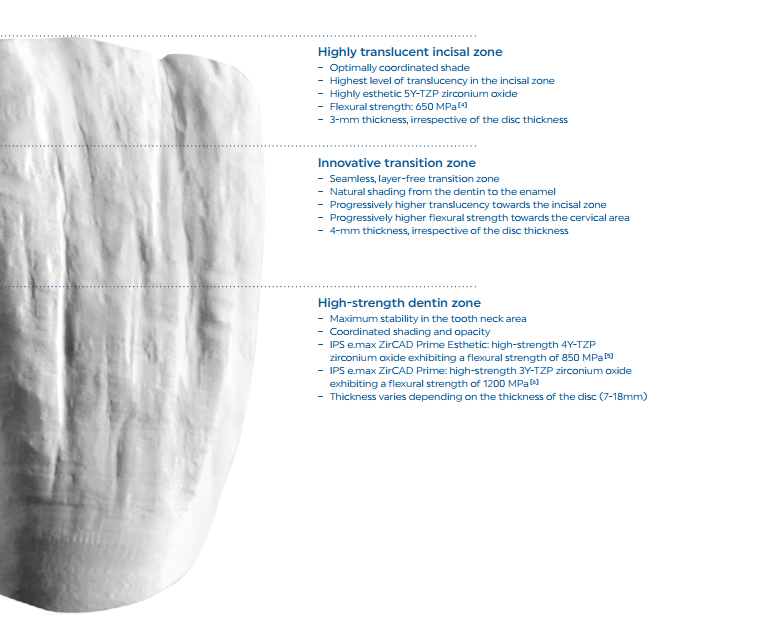

Rather than using a single material for the entire restoration, the optimal solution is to combine different types of zirconia according to specific functional zones:

- Dentin / cervical / abutment regions: require high flexural strength and excellent resistance to crack propagation to withstand substantial mechanical loads.

- Incisal region: requires high translucency, good surface stability, resistance to aging, and excellent polishability.

By combining ultra-high-strength zirconia in load-bearing areas with highly translucent zirconia in esthetic zones, the risk of chipping is significantly reduced. At the same time, manual steps such as extensive veneering and multiple firing cycles can be eliminated or greatly reduced. As a result, laboratories save time, minimize technical variability, and still achieve a very high level of esthetics.

The irreplaceable role of 3Y-TZP in large restorations

Yttria-stabilized tetragonal polycrystalline zirconia—3Y-TZP—remains the “core material” for restorations subjected to high mechanical stress, such as:

- Long-span bridges

- Frameworks

- Abutment crowns in full-arch restorations

These restorations are often exposed to cyclic tensile stresses in connector areas and abutment crowns. If the material lacks sufficient resistance to crack propagation, long-term stability can be severely compromised. For this reason, 3Y-TZP, with its very high flexural strength and fracture toughness, remains an irreplaceable choice in these critical regions.

Challenges of 3Y-TZP in occlusal areas and the oral environment

Despite its advantages, 3Y-TZP also has inherent limitations. When used directly in occlusal areas and when the zirconia surface is left exposed to the oral environment, the material may undergo low-temperature degradation (LTD).

This phenomenon can lead to:

- Spontaneous phase transformation to the monoclinic phase

- Increased surface roughness

- Increased wear of the opposing dentition

Such microstructural surface changes not only affect the longevity of the restoration but can also negatively impact the overall masticatory system.

Increasing yttrium content – the key to surface stability

The solution to these challenges is to increase the level of zirconia stabilization, particularly in the incisal region. Zirconia with a higher yttrium content—5Y-TZP (5 mol% Y₂O₃)—demonstrates the ability to:

- Minimize spontaneous formation of the monoclinic phase

- Reduce aging effects in the oral environment

- Maintain a stable surface with minimal changes in roughness over time

As a result, issues related to antagonist wear and long-term esthetic degradation can be effectively controlled.

Tiếng Việt

Tiếng Việt